| 30 August 2023

Fusion 360: Elevating Product Design with Innovative and Efficient CAD Software

Want to get Fusion 360 training? Use our discount code fab23 for our next event, click here to book your spot

We Fabbers know that time and resources are really valuable when prototyping. With that in mind we would like to tell you why we have chosen Fusion 360 as our preferred CAD/CAM software. Integrating into our digital fabrication pipeline, Fusion empowers designers and creatives to bring their visionary concepts to life.

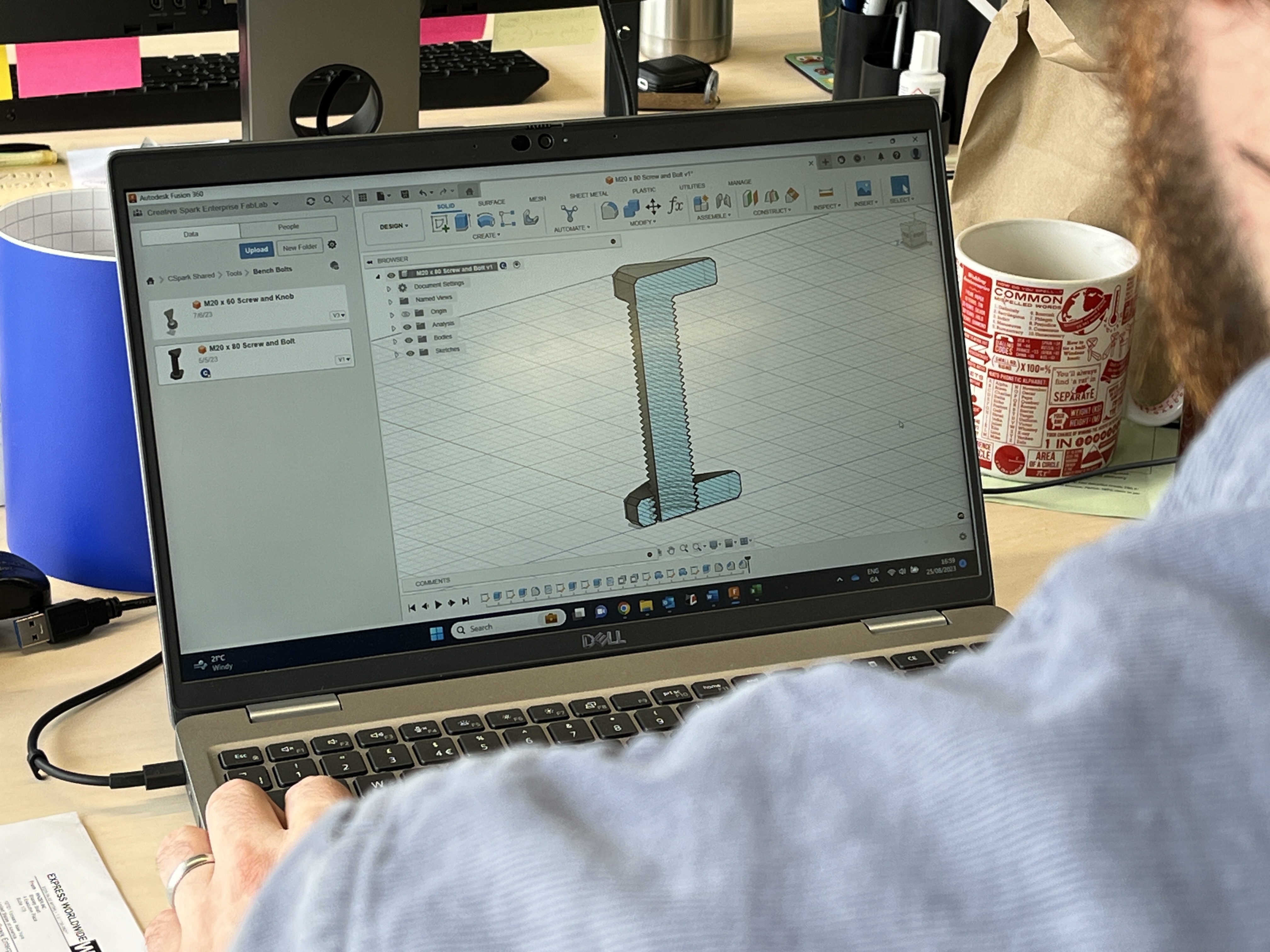

Forge intricate designs with powerful CAD tools that span solid modelling, surface modelling, and T-spline modelling. From the conceptual stage to the refined prototype, Fusion 360's user-friendly interface ensures that your design journey remains intuitive and fluid.

Image 1. Section view in Fusion 360.

Affordability meets capability, as Fusion 360 opens doors to professional-grade design without breaking the bank. Our FabLab invites you to access this cutting-edge tool, transcending financial constraints while unleashing your creative brilliance.

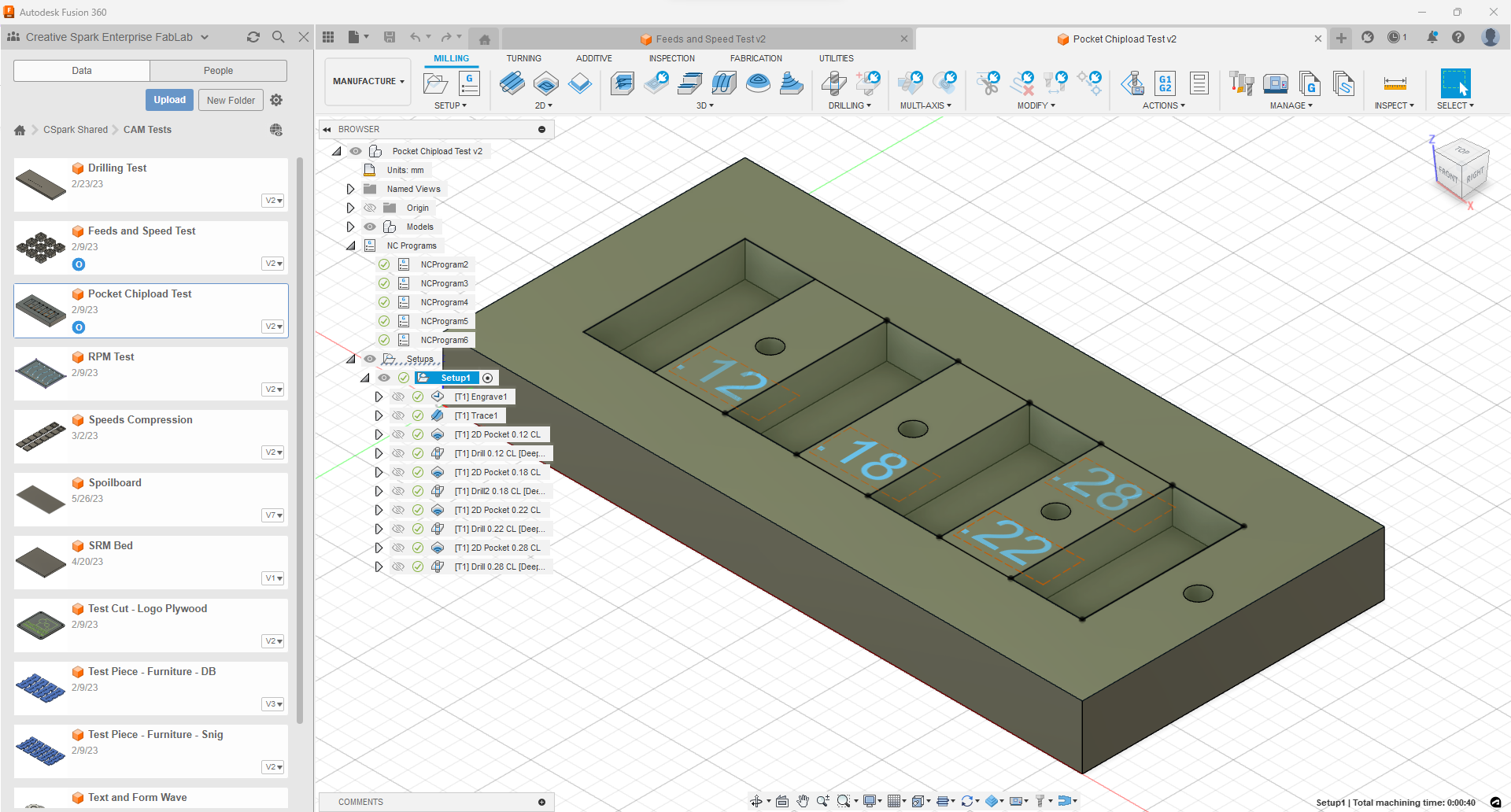

Fusion 360 offers an array of distinct advantages when employed within a FabLab environment that leverages a diverse range of equipment for rapid prototyping. This powerful software seamlessly integrates with FabLab tools, such as 3D printers, laser cutters, CNC machines, and more, providing a comprehensive platform for innovators to efficiently bring their ideas to life.

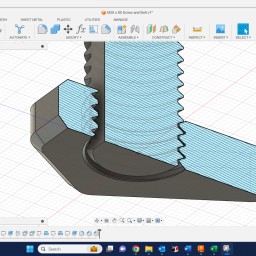

Image 2. Chipload test prepared using Fusion 360 to be done with a ShopBot CNC.

Advantages of utilizing Fusion 360 in a FabLab setting include:

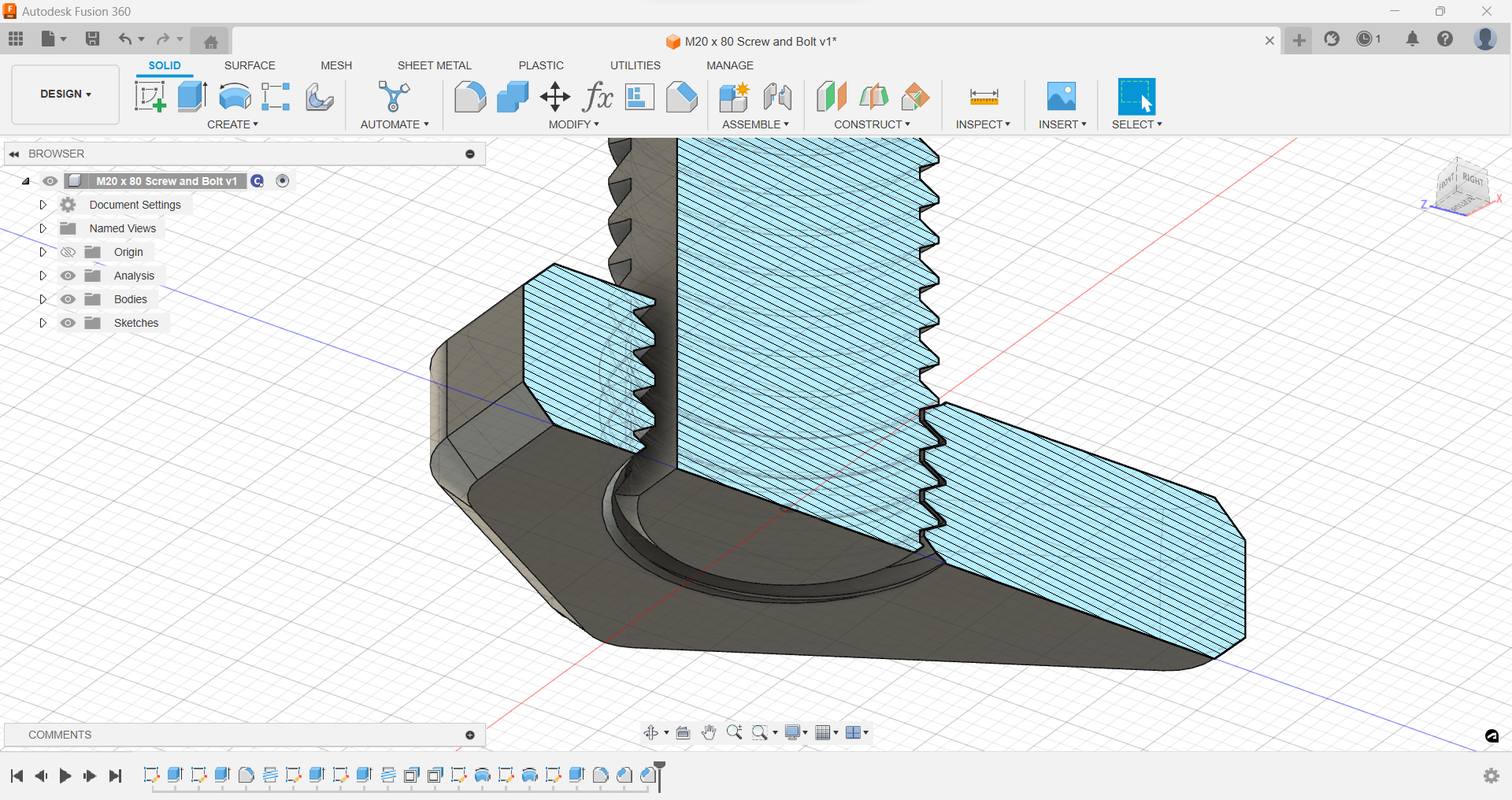

- Unified Platform: Fusion 360 serves as an all-in-one solution, enabling users to design, simulate, and generate toolpaths for various equipment in a single interface, streamlining the prototyping process.

- Parametric Design: The software's parametric modelling capabilities facilitate quick iteration and modification of designs, aligning perfectly with the iterative nature of rapid prototyping.

- Collaborative Workflow: Fusion 360 enables real-time collaboration, allowing teams to work on designs simultaneously, share feedback, and optimize prototypes collectively, regardless of geographical location.

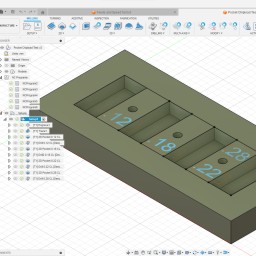

- 3D Printing Optimization: Seamless integration with 3D printers ensures that designs can be prepared and sliced accurately for optimal printing, minimizing material wastage and production time.

- Laser Cutting Precision: Fusion 360's vector-based workflows make it effortless to create intricate 2D designs for laser cutting, ensuring precision and enhancing the quality of finished prototypes.

- CNC Machining Efficiency: With integrated CAM tools, Fusion 360 assists in generating toolpaths for CNC machines, transforming digital designs into tangible prototypes with high accuracy.

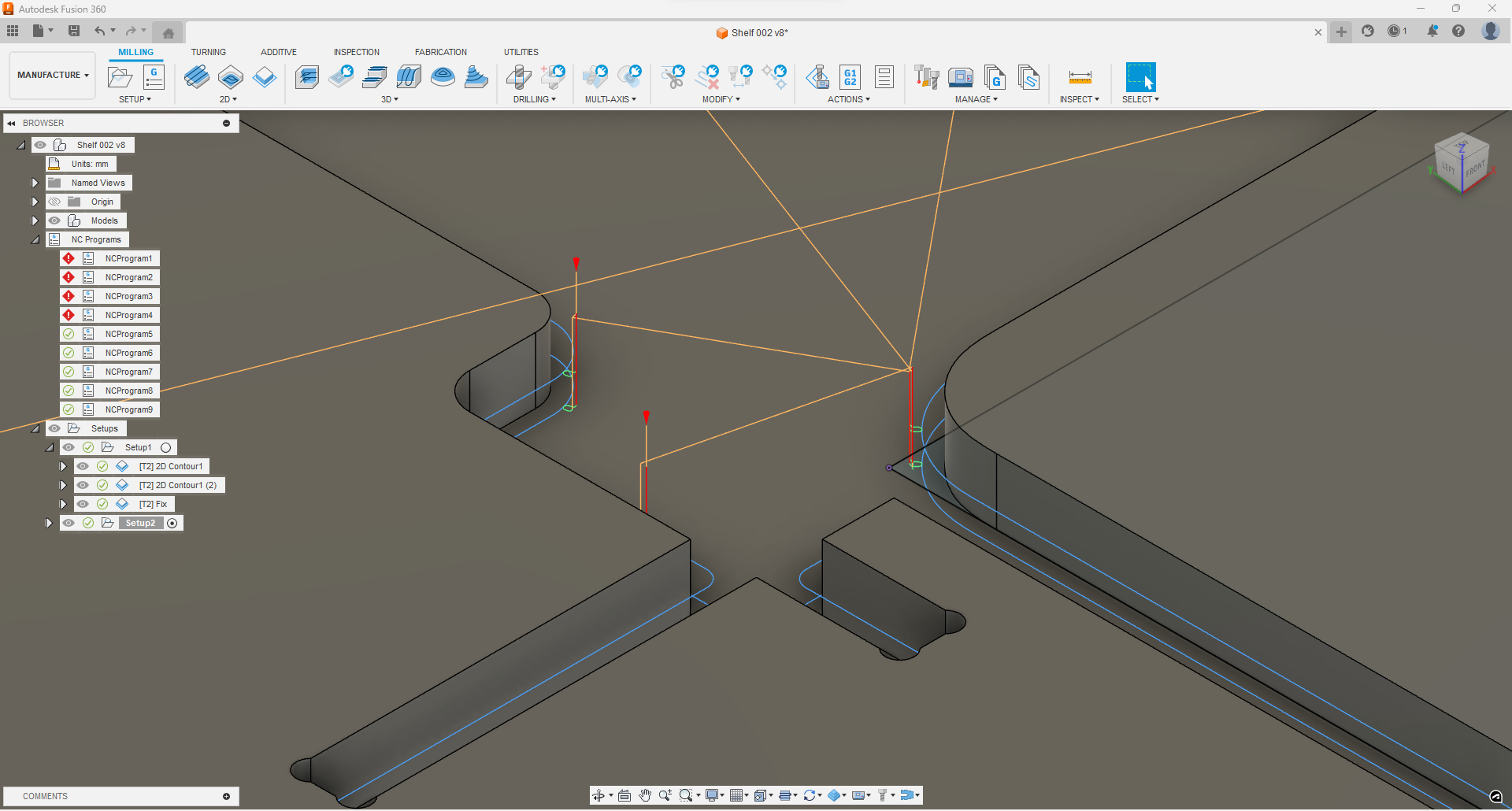

Image 3. CAM preparation setting upt toolpaths for each process.

- Simulation and Testing: The software's simulation capabilities aid in evaluating the functionality and durability of prototypes virtually, reducing the need for physical iterations and improving overall design quality.

- Material Compatibility: Fusion 360 offers a diverse library of materials, enabling users to select the most suitable material for their prototypes, considering factors like strength, flexibility, and appearance.

- Training Resources: Autodesk provides extensive learning resources for Fusion 360, making it accessible even to newcomers in the FabLab environment, thus empowering a wider range of innovators.

- Cost-Effectiveness: By minimizing the need for manual adjustments, rework, and material wastage, Fusion 360 optimizes the prototyping process, contributing to overall cost savings.

Image 4. SLS 3D printed part design using Fusion 360.

Incorporating Fusion 360 into a FabLab environment amplifies the potential for creativity, accelerates the design-to-prototype timeline, and fosters a collaborative ecosystem where makers can efficiently transform their ideas into tangible realities using a diverse range of rapid prototyping equipment.

Our FabLab beckons designers and creatives to engage in this transformative experience. Step into Fusion 360 and discover a powerful CAD capabilities converge with user-friendliness and affordability.

Try it now at https://www.autodesk.com/products/fusion-360/personal

Recent Posts

18 December 2024

Creative Spark Enterprise FabLab proudly represented Ireland at the recent Fab24 Mexico conference, Fabricating Equity, organized by IDIT Institute of Design and Technological Innovation and the Fab Foundation.

27 November 2024

Sustainable Fashion Co-Creational Project starting January 2025!

22 November 2024

Louth-based artist and textile specialist Claire McAteer has joined Creative Spark as its newest Artist-in-Residence. Focused on drawing, print, embroidery, collage, and felt.